| Sign In | Join Free | My qualitytoyschina.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My qualitytoyschina.com |

|

Brand Name : KUNYA

Model Number : KYF210415A

Place of Origin : China

MOQ : 1 piece

Price : Negotiable

Payment Terms : T/T

Supply Ability : 158741000 pieces per month

Delivery Time : 15-20 days

Packaging Details : wooden case

Product name : Sintered Metal Porous Filter

Thickness : 1.0mm-5.0mm

Filter rating : 1um-300um

Application : Food & Beverage Factory, Energy & Mining, Petro chemical

Usage : Water treatment Oil products Food beverage

Weave style : plain weave, twill weave, dutch weave

Mesh count : 1 Mesh - 8000 Mesh

Material : 304SS 316SS 316L

Efficiency : 95 - 99%

Style : Cylinder Cartridge Candle

Feature : Excellent Filtration

After-sale service : Video technical support

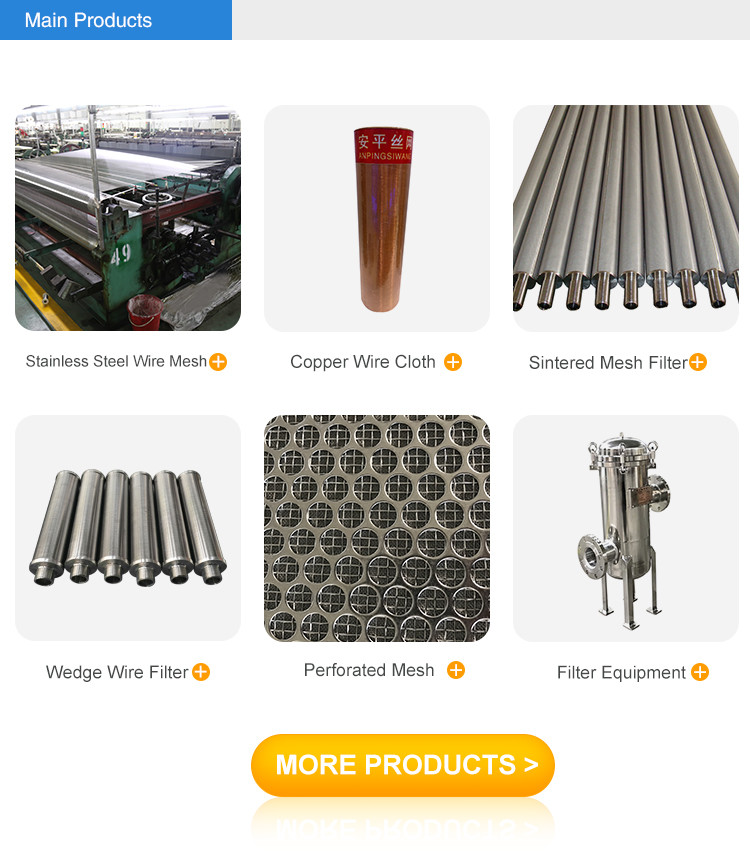

Kunya designs and manufactures high-performance sintered metal fiters and filtration material products for all industries such as sintered metal fiber felt, multi-layers sintered wire mesh, ss sintered filter cartridges,porous metal fiters and material-specific filters like sintered nickel filters.

Compare to common metal woven wire mesh,Filson sinter fiters have excellent strength, long lifespan, and good anti-corrosion. Meanwhile, we can offer custom dimensions, materials, and layering configurations to meet your exact specifications.

Please send us your medium kinds,flow rate,fitration accuracy, material request or even ideal sintered meta ifiter elements with other brands, Like Mott filter,CKN sinter metals filters,Norman sintered metal filter elements,then we will quote for you immediately.

The main filter material of Five-layer Sintered Mesh Filter Cartridge adopts standard five-layer sintered mesh which is processed by five-layer stainless steel screen superposition and vacuum sintering. Filters made of this kind of material has some excellent characteristics such as strong corrosion resistance, good permeability, high strength, easy to wash and backwash, accurate filtration precision, clean filter medium, without wire net falling off etc.

Sintered Metal Porous Filter Application:

Used for filtration of polyester, water treatment, oil product, pharmaceutical, food and beverage, chemical industry, chemical fiber products and medium filter such as high temperature air.

1. Standard interface (e.g 222, 220, 226 etc.)

2. Fast interface connection

3. Threaded connection

4. Flange connection

5. Tie rod connection

6. Special custom interface

1) high flow, high precision

2) high porosity, permeability, pressure drop very low

3) excellent mechanical strength, resistance to high pressure up to 200Kg

4) easy to clean, backpulsing

5) corrosion resistance, high temperature resistance

6) good processing performance, folding, welding, adhesive

7) design flexibility

8) 80-200l/min - rated flow; working pressure 1.5-2.5pa; filtering area (M2) 0.01-3.0; (m) 2-200. filtering accuracy

|

|

20micron 50micron 100micron 304ss Candle Weave Sintered Filter Elements Images |